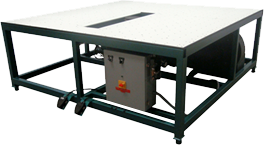

AUTO SEAL APPLICATOR TABLE

PRODUCT DESCRIPTION

FEATURES

Automatic cup movement TOWARD and AWAY from the operator during lite rotation assures that the glass edge remains on the table and is positioned correctly so that the sealing operator can work quickly & efficiently.

The PST Auto Seal Applicator Table includes manual cup rotation for operator safety and is equipped with extra heavy duty 5 HP full plenum air flotation for ease of glass movement. Its superior construction insures high reliability and maintenance free operation.

MECHANICAL FEATURES

Applicator Table is available in sizes of 60" x 60" , 72" x 72", 84" x 84" or 96" x 96" . The table frame is fabricated from 3" x 2" heavy wall tubular steel with 100% MIG welded construction.

The table is equipped with 5 HP Plenum air floatation unit and a dedicated air supply source for operating the applicator tool. The 96” x 96” table size comes standard equipped with a 10 hp plenum air flotation.

The superiorly constructed table top is fabricated from highly durable Arborite solid slab material which increases the life of the table.

The pneumatic rodless cup actuating cylinder allows for exceptionally smooth operation. The operating sequence is PLC controlled for improved processing and mechanical reliability.

The table is equipped with a heavy duty linear way system and a pneumatic cylinder for movement of vacuum cup holding mechanism with a heavy duty construction for long life & maintenance free operation. All table edges are trimmed with renewable nylon edging to prevent damage to the table top covering.

OPERATING SEQUENCE

The operator slides a glass lite onto the table and centers the lite over the vacuum cup then presses a foot pedal switch raising the vacuum cup which adheres to the glass lite. The operator then applies the sealing tape to the first lite and presses a foot switch to turn the glass. As the operator turns the glass lite, the applicator table automatically maintains the edge of the glass onto the table surface and locks at 90 degrees.

The glass edge is positioned to the front edge of the table, at all times, so that operator can efficiently apply sealing tape. Glass positioning movements are repeated three times during the sealing cycle. After the last side is completed, the vacuum cup is released by activating the foot pedal switch. The first lite, with sealing tape attached, can now be pushed onto a Tilt Top Grid Assembly Table.

Ships FOB Dallas, TX

© COPYRIGHT 2014 ALL RIGHTS RESERVED PERFECT SCORE TECHNOLOGIES

The PST Auto Seal Applicator Table is designed to enable manufacturing personnel to quickly apply sealing spacer to the first glass lite of an insulated unit.

FEATURES

Automatic cup movement TOWARD and AWAY from the operator during lite rotation assures that the glass edge remains on the table and is positioned correctly so that the sealing operator can work quickly & efficiently.

The PST Auto Seal Applicator Table includes manual cup rotation for operator safety and is equipped with extra heavy duty 5 HP full plenum air flotation for ease of glass movement. Its superior construction insures high reliability and maintenance free operation.

MECHANICAL FEATURES

Applicator Table is available in sizes of 60" x 60" , 72" x 72", 84" x 84" or 96" x 96" . The table frame is fabricated from 3" x 2" heavy wall tubular steel with 100% MIG welded construction.

The table is equipped with 5 HP Plenum air floatation unit and a dedicated air supply source for operating the applicator tool. The 96” x 96” table size comes standard equipped with a 10 hp plenum air flotation.

The superiorly constructed table top is fabricated from highly durable Arborite solid slab material which increases the life of the table.

The pneumatic rodless cup actuating cylinder allows for exceptionally smooth operation. The operating sequence is PLC controlled for improved processing and mechanical reliability.

The table is equipped with a heavy duty linear way system and a pneumatic cylinder for movement of vacuum cup holding mechanism with a heavy duty construction for long life & maintenance free operation. All table edges are trimmed with renewable nylon edging to prevent damage to the table top covering.

OPERATING SEQUENCE

The operator slides a glass lite onto the table and centers the lite over the vacuum cup then presses a foot pedal switch raising the vacuum cup which adheres to the glass lite. The operator then applies the sealing tape to the first lite and presses a foot switch to turn the glass. As the operator turns the glass lite, the applicator table automatically maintains the edge of the glass onto the table surface and locks at 90 degrees.

The glass edge is positioned to the front edge of the table, at all times, so that operator can efficiently apply sealing tape. Glass positioning movements are repeated three times during the sealing cycle. After the last side is completed, the vacuum cup is released by activating the foot pedal switch. The first lite, with sealing tape attached, can now be pushed onto a Tilt Top Grid Assembly Table.

Ships FOB Dallas, TX

© COPYRIGHT 2014 ALL RIGHTS RESERVED PERFECT SCORE TECHNOLOGIES

Download our line card

Click Shop above to browse our NEW e-commerce site

Precision Solutions for Cutting and Glass Processing Excellence

- Aculite CNC Cutting

- Glass Machinery

- Glass Processing Tables

- Auto Freefall Glass Loading

- Insulated Unit Assembly

- Automatic Applicator Table

- Tilt Top Grid Assembly Table

- Prem. Auto Seal Applicator Table

- Prem. HTT Applicator Table

- Easel Grid Table

- LKO Rotating Sealing Table

- Power Rotating Sealing Table

- Cold Single Set Roller Press

- KKO-17 Rotating Sealing Stand

- Hot Melt Clamp Table

- Desiccant Filling Machine

- Application & Hot Melt Clamp

- Low-E & Glass Processing

- Glass Inspection Units

- Glass Storage Racks

- Glass Washing Equipment

- Glass Lifting Devices

- Waterjet Machinery

- Glass & Glazing Supplies

- Machine Parts

- Services

- Software

- Video Demos