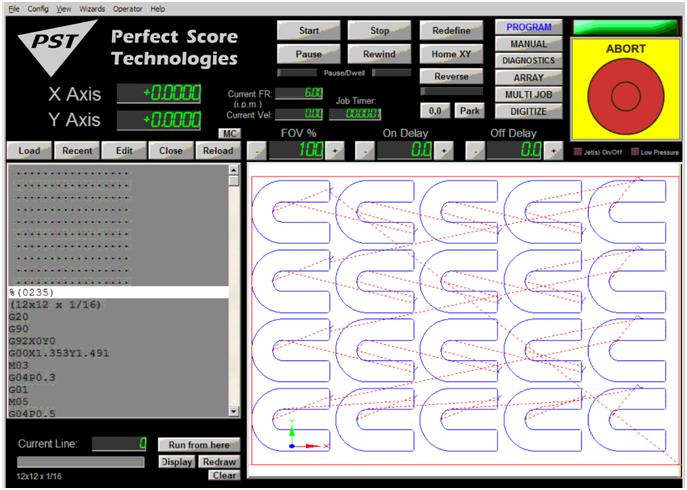

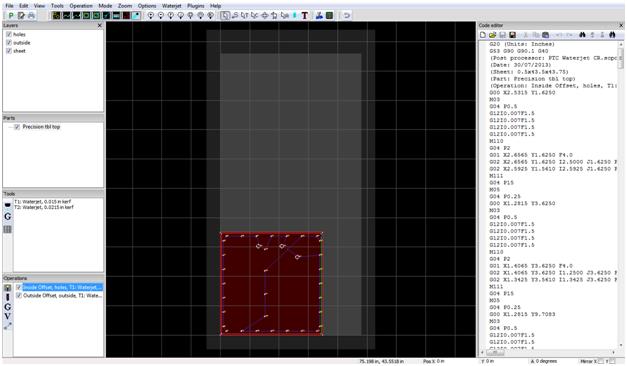

PST Waterjet Operating Software - Standard

This software executes G code cut files input from the Post Processing software. All decisions are accounted for within the G code file to include – cut / corning speeds, auto piercing, type of lead-in. The operator simply loads material, inputs cut file and pushes the start button. Actual cutting functions can be operator monitored to include - specific line of code executed, x & y positioning, and color designated tool paths. The operator can simply change cut speeds on the fly, pause cutting or run in reverse. Even has the ability to automatically execute in sequence multiple (jobs) cut files providing independent soft home locations.

•

Windows based software.

•

Interactive Tool Path – color designates the executed path and actual cut location.

•

Pause , Reverse features.

•

Operator Feed Rate Override - on the fly.

•

Head up / Head down control.

•

Soft Home – assign alternate home positions.

•

Go To – go to any location with cut file.

•

Operator Array - allows the operator to quickly array multiple parts on a sheet without reprocessing file.

•

Multiple File Loading – executes up to 6 job files in sequence.

•

File Rotation – no need to move heavy material just type in desired angle.

•

Operating Time – displays actual job cutting time.

•

Fixtures – file adjustment on the fly to accommodate for tooling fixtures.

•

Remote Pendant Controller - standard equipment, allows for operator manual control.

•

Height Sensing - available

•

Auto Drill - available

•

Ink Jet compatible - available

** SOFTWARE UPGRADE IS FREE FOR LIFE TO THE ORIGINAL MACHINE OWNER **

PST Post Processing Software - Standard

The sole purpose of the post processing software package is to transform a drawing file ( CAD, DWG, DXF) to a water jet cut ready file (G code). PST Post Processing software is included standard with each waterjet system. The popular features as listed below will satisfy the majority of users. For more complex and automated cutting requirements PST also offers Lantek software.

•

Generate tool paths.

•

Calculates kerf width (inside, outside & center).

•

Lead in/Lead out (Automatic placement, several styles).

•

Spiral Piercing and pressure control.

•

Corner ramping.

•

Import DXF files.

•

Tabbed parts.

•

Manual Nesting.

•

Array parts.

•

Preview/edit generated GCode.

•

Simulation mode.

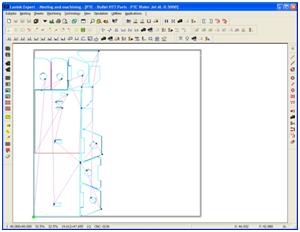

Advanced Post Processing Software - Optional

Lantek software can be purchased as an option for advanced waterjet users having complex

cutting requirements. The PST waterjet operating software is fully compatible with Lantek,

users can upgrade if and as needed. The Lantek company has twenty five years of experience

with a staff of 160 employees dedicated to perfecting this software. Many users may only use

basic functions with others eager to use every available feature. Lantek offers 24 hour

customer support with offices worldwide. Users operating machining centers have the ability to integrate their operations to a

single software package – punch, shears, CNC, lasers, routers, waterjets. Every feature has been perfected to world class

performance, the AutoNest capability is viewed as best in the industry. This is a very sophisticated program developed over

several decades.

LANTEK EXPERT 1 - optional software package

Material Data Tech Tables

Select material type, thickness, desired edge quality

Calculates -cut speed, kerf & corner compensation, accelerations, tool paths, lead-in.

2D Cad Drawing Package

Automatic dimensioning

Parametric Shapes Library

Import Files - DXF, DWG,WMF, MEC

MEC Import Module

Automatic geometry verification and error correction

Geometry Verification & Error correction - closes open end drawing files

Speed Reduction on Corners - maintains a perpendicular cut edge.

Lead in and Lead out - Multiple styles to choose.

- Automatic generation and placement

- Overlapping detection and correction

Collision Avoidance - user can not accidentally overlap parts while manually nesting.

Flexible automatic sequencing options

Common Line cutting - compensates for kerf width.

Bridge cutting and pierce reduction

Multiple Hole Piercing Options - material and speed dependant

Variable Cut Smoothness - tailor each individual part segment from rough to smooth.

Integrated Parts Database

Integrated Material Database - a Tech Library of all materials.

Standard reports (Factory sheets report, Sheets report, Geometry report.

Parts report, Labels report, Time and Cost reports, etc)

Automatic part quantity tracking

Automatic calculation of part area, weight, machining time and cost

User-definable cost parameters

LANTEK EXPERT 2 - Optional Nesting Software

Nesting, including parts within parts

Automatic nesting on remnant sheets

Multi-head nesting on remnants

Nesting for multiple cutting heads.

Multiple Sheet Nesting

Array nesting

Material Data Tech Tables

Select material type, thickness, desired edge quality

Calculates -cut speed, kerf & corner compensation, accelerations, tool paths, lead-in.

2D Cad Drawing Package

Automatic dimensioning

Parametric Shapes Library

Import Files - DXF, DWG,WMF, MEC

MEC Import Module

Automatic geometry verification and error correction

Geometry Verification & Error correction - closes open end drawing files

Speed Reduction on Corners - maintains a perpendicular cut edge.

Lead in and Lead out - Multiple styles to choose.

- Automatic generation and placement

- Overlapping detection and correction

Collision Avoidance - user can not accidentally overlap parts while manually nesting.

Flexible automatic sequencing options

Common Line cutting - compensates for kerf width.

Bridge cutting and pierce reduction

Multiple Hole Piercing Options - material and speed dependant

Variable Cut Smoothness - tailor each individual part segment from rough to smooth.

Integrated Parts Database

Integrated Material Database - a Tech Library of all materials.

Standard reports (Factory sheets report, Sheets report, Geometry report.

Parts report, Labels report, Time and Cost reports, etc)

Automatic part quantity tracking

Automatic calculation of part area, weight, machining time and cost

User-definable cost parameters

LANTEK EXPERT 2 - Optional Nesting Software

Nesting, including parts within parts

Automatic nesting on remnant sheets

Multi-head nesting on remnants

Nesting for multiple cutting heads.

Multiple Sheet Nesting

Array nesting

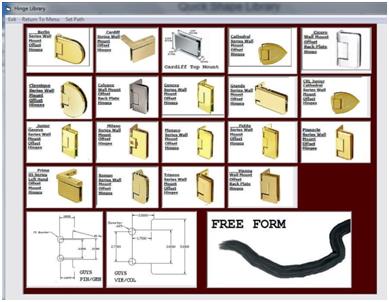

PST Glass Hardware Library - standard

Ready to go shape library for Glass Fabricators.

Shapes are selected and dropped directly into the drawing file.

Shape Library providing hinge and hardware items.

Provided standard with PST Post Processing Software package.

Ready to go shape library for Glass Fabricators.

Shapes are selected and dropped directly into the drawing file.

Shape Library providing hinge and hardware items.

Provided standard with PST Post Processing Software package.

Download our line card

Click Shop above to browse our NEW e-commerce site

Precision Solutions for Cutting and Glass Processing Excellence

- Aculite CNC Cutting

- Glass Machinery

- Glass Processing Tables

- Auto Freefall Glass Loading

- Insulated Unit Assembly

- Automatic Applicator Table

- Tilt Top Grid Assembly Table

- Prem. Auto Seal Applicator Table

- Prem. HTT Applicator Table

- Easel Grid Table

- LKO Rotating Sealing Table

- Power Rotating Sealing Table

- Cold Single Set Roller Press

- KKO-17 Rotating Sealing Stand

- Hot Melt Clamp Table

- Desiccant Filling Machine

- Application & Hot Melt Clamp

- Glass Processing Equipment

- Glass Inspection Units

- Glass Storage Racks

- Glass Washing Equipment

- Glass Lifting Devices

- Waterjet Machinery

- Glass & Glazing Supplies

- PST Machine Parts

- Services

- Software

- Video Demos