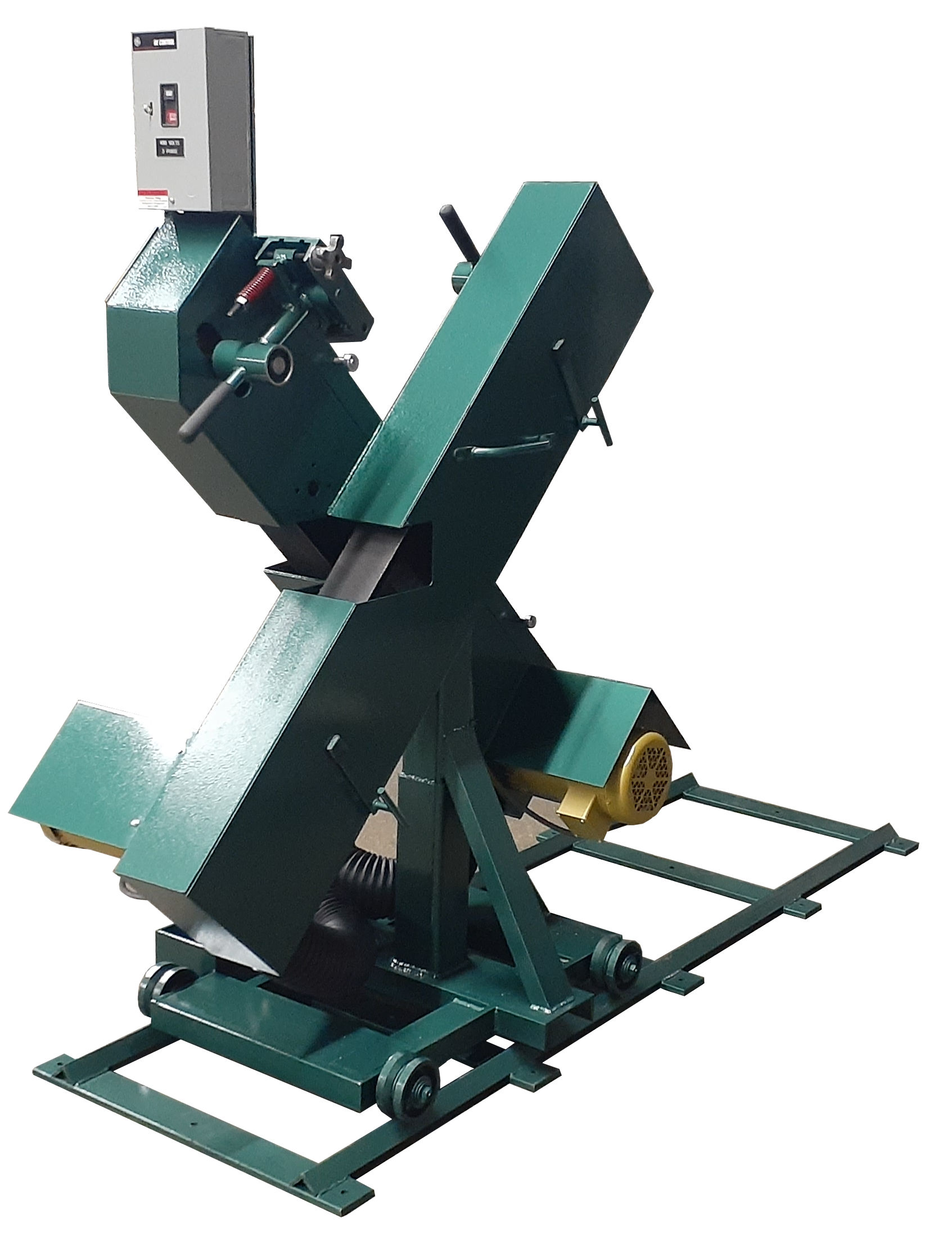

For tempering plants utilizing horizontal systems with glass washing machines, the PST Wet/Dry Glass Twin Seamer is an ideal choice.

Constructed with a steel frame made entirely from ¼-inch welded plates, this system offers:

Independently driven powerful 1 HP motors

Oversized stress-proof drive shafts for enhanced fatigue strength and durability

A short belt throat distance, facilitating easy glass lite seaming

The ability to effortlessly create two seamed edges on a glass lite in a single pass

Separate spray valves to control water distribution to each belt.

Back stand idler enables on-the-fly adjustments, including:

Quick belt tracking

Tensioning

Take-up

This eliminates production downtime, unlike competitive

machines that necessitate shutdowns for adjustments.

Durable DTM Alkyd Enamel Coating, providing:

Long lasting protection

Superior adhesion

Corrosion resistance

Ideal for heavy-duty equipment

Engineered for compatibility with wet belts, offering:

Faster sanding

Extended durability

Dust-free operation

Fully hooded belts to maintain a clean working area, preventing belt spray.

Options and Accessories:

Optional Rail Track Roller Mounting for ease of mobility.

Roller Platen Accessory sold separately.

When equipped with a dust collector, the Seamer can operate in dry mode.

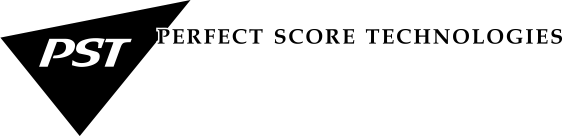

SPECIFICATIONS

Twin 1 HP motors, available in 208, 230, or 480 volts, 3 Phase, 60 Hz, 3.4 - 6.8 Amps

Weight: 600 pounds

Shipping Dimensions: 62 x 40 x 72

Belts: Utilizes standard 4” x 106 wet abrasive belts, with a selection of grit options

Base Dimensions: 33” in width, 33” in length, seaming height adjustable between 34 to 36”

Finish: Coated with DTM Alkyd green enamel

Twin Seamer Accessory Line:

Twin Seamer Ball Caster Tables

Designed to complement the Wet/Dry Twin Seamer, the PST Ball Caster Table simplifies the seaming process by

providing crucial glass support, ensuring the operator can efficiently seam all four edges without experiencing fatigue.

Extending 38 inches on both sides of the cutout, this table accommodates glass widths of up to 72 inches or more.

The operator cutout measures 14 inches by 22 inches with ball casters spaced either 6" x 8" or 12" x 12".

Crafted with an all-welded construction, the table incorporates neoprene rubber ball casters for smooth and reliable operation.

An optional extension is available, which may be pulled out and locked into place.

This extension allows the operator to easily work with larger glass sheets and can be retracted for smaller sheets of glass

The Twin Seamer Air Flotation Table works in conjunction with the Wet/Dry Glass Twin Seamer.

This table is designed to facilitate twin seaming by providing essential glass support.

It effectively bears the weight of the glass, reducing operator fatigue.

This support enables the operator to seam all four glass edges quickly and efficiently.

The table comes equipped with a 3 HP (or optional 5 HP) full plenum air flotation system.

The air flotation system operates on 208, 230, or 480 volts, 3-phase power (Buyer to specify the desired voltage).

PST WET/DRY GLASS TWIN SEAMER & MACHINE PARTS

Front view

Side view

Wet/Dry components

Twin Seamer Dust Collectors (Optional 2HP, 3HP and 3HP w/HEPA)

The 2HP canister-style dust collector features a convenient filter cleaning handle that, when rotated, dislodges accumulated debris into the lower collection bag.

The 3HP totally enclosed dust collector is built with heavy duty industrial quality and removes particles down to a level of 3 microns in size.

The 3HP with Hepa dust collector is capable of removing particle size down to level of 1/2 micron. HEPA unit removes 99.97% of all particles while reducing CFM of unit.

Click Shop above to browse our NEW e-commerce site

- Aculite CNC Cutting

- Glass Machinery

- Glass Processing Tables

- Auto Freefall Glass Loading

- Insulated Unit Assembly

- Automatic Applicator Table

- Tilt Top Grid Assembly Table

- Prem. Auto Seal Applicator Table

- Prem. HTT Applicator Table

- Easel Grid Table

- LKO Rotating Sealing Table

- Power Rotating Sealing Table

- Cold Single Set Roller Press

- KKO-17 Rotating Sealing Stand

- Hot Melt Clamp Table

- Desiccant Filling Machine

- Application & Hot Melt Clamp

- Glass Processing Equipment

- Glass Inspection Units

- Glass Storage Racks

- Glass Washing Equipment

- Glass Lifting Devices

- Waterjet Machinery

- Glass & Glazing Supplies

- PST Machine Parts

- Services

- Software

- Video Demos