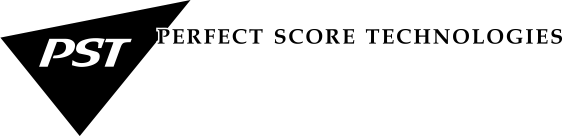

CARBIDE CUTTING WHEELS, AXLES & INSERTS

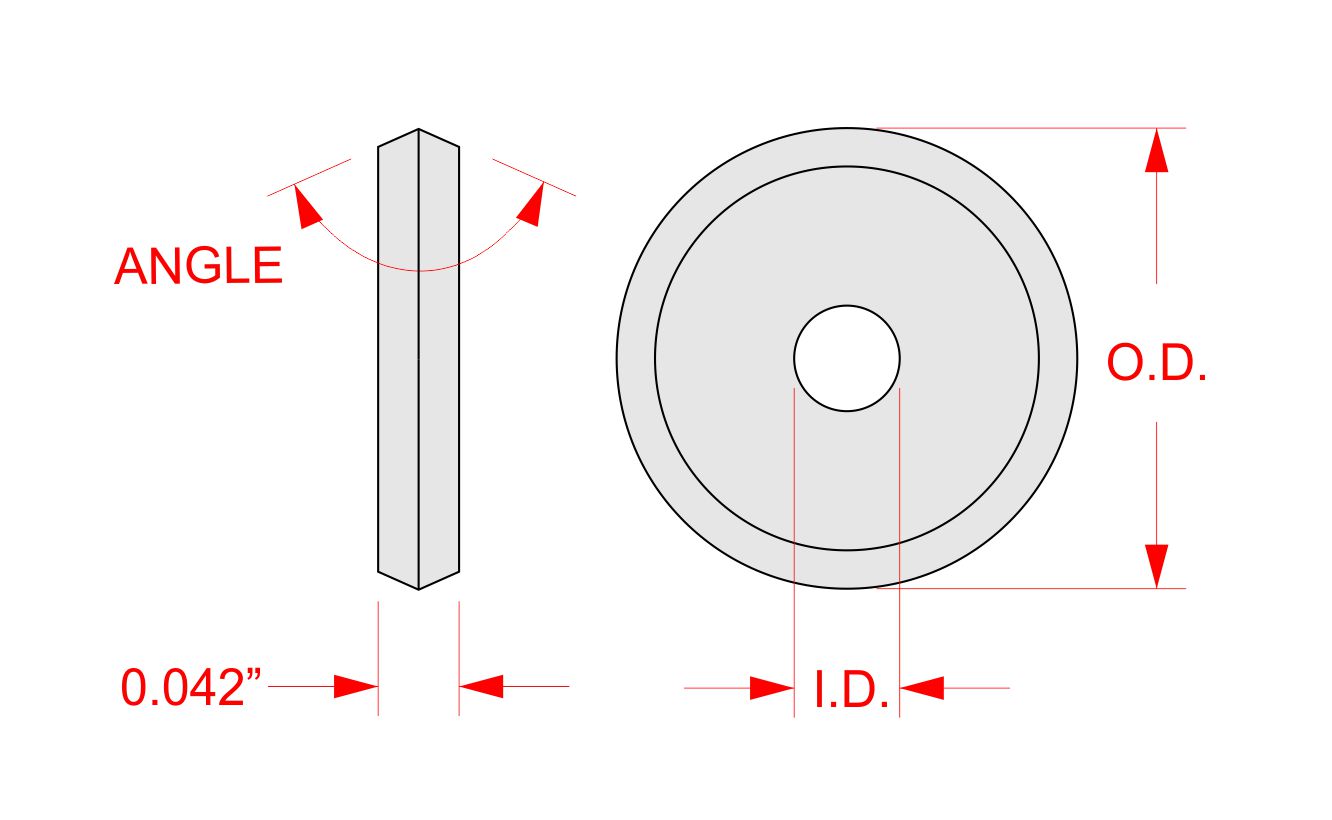

| Perfect Score Standard Tungsten Carbide Wheels Compatible with AC-054 axles and PST M1 Insert |

|||||||

| MODEL | ANGLE | DIMENSIONS | |||||

| 124 | 134 | 140 | 144 | 154 | OD | ID | |

| PS215-055- | 🗸 | 🗸 | 🗸 | 🗸 | 🗸 | 0.215" | 0.055" |

| PS240-055- | 🗸 | 🗸 | 🗸 | 🗸 | 🗸 | 0.24" | 0.055" |

| PS175-055- | 🗸 | 🗸 | 🗸 | 0.175" | 0.055" | ||

| Quantity | Price |

| 1-15 | View in cart |

| 16-99 | " |

| 100-249 | " |

| 250+ | " |

*All Pricing is FOB Dallas, TX

$100.00 Minimum Purchase Required

Minimum may include a combination of Cutting Wheels, Inserts and Axles

Minimum may include a combination of Cutting Wheels, Inserts and Axles

| Perfect Score L-Style Tungsten Carbide Wheels Compatible with LAC-051 axles and Lisec Insert |

|||||||

| MODEL | ANGLE | DIMENSIONS | |||||

| 124 | 134 | 140 | 144 | 154 | OD | ID | |

| LPS185-051- | 🗸 | 🗸 | 🗸 | 🗸 | 0.185" | 0.051" | |

| Quantity | Price |

| 1-24 | View in cart |

| 25-99 | " |

| 100+ | " |

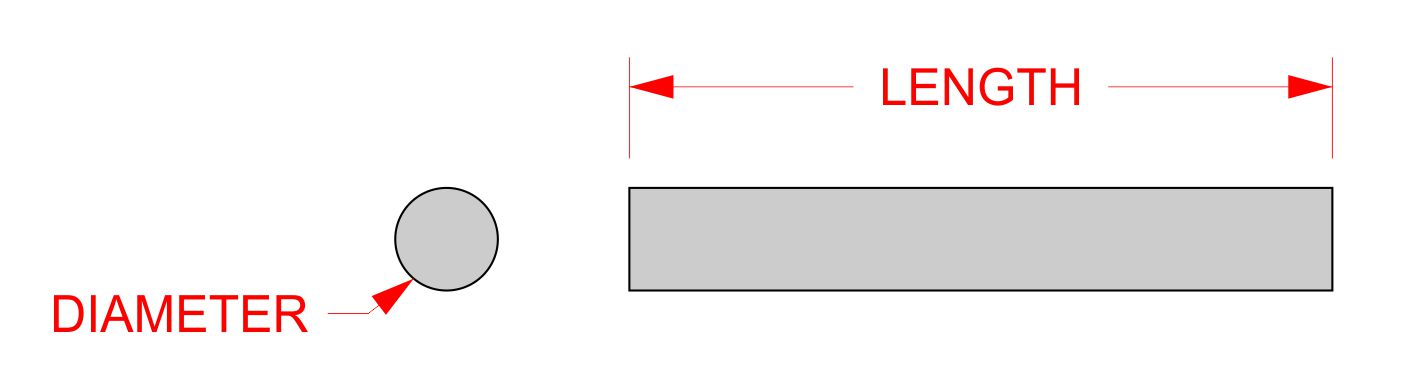

| Perfect Score Tungsten Carbide Axles | |||

| MODEL | DIMENSIONS | PRICE | |

| Diameter | Length | ||

| *AC-054-173 | 0.054" | 0.173" | View in cart |

| *AC-054-180 | 0.054" | 0.180" | " |

| *AC-054-370 | 0.054" | 0.370" | " |

| *LAC-051-315 | 0.051" | 0.315" | " |

* Compatible with PSxxx-055 wheels and M1 Insert

** Compatible with LPS185-051 Wheels and Lisec Inserts

| Perfect Score M1 Insert Fits PTC/PST, GED, Billco, Bystronic & Hegla Tables MTI & Bavelloni Posts |

|||

| MODEL | DIMENSIONS | PRICE | |

| Wheel Slot | Axle OD | ||

| ***PSM1-43 | 0.435" | 0.54" | View in cart |

*** Requires axle part #AC-054-180

Upgrading consumable parts on your automatic glass cutting and scoring equipment can significantly enhance its performance and ensure precise, flawless cuts. Replacing glass cutting wheels, wheel axles, and wheel inserts brings about several benefits, such as:

Improved Precision: Upgrading to high-quality cutting wheels ensures smoother and more accurate glass cuts, reducing errors and waste.

Extended Lifespan: Regular replacement of consumable parts enhances the overall durability of the equipment, minimizing downtime and maintenance costs.

Versatility: Choose between two cutting wheel styles—standard and L-style—to tailor your equipment to specific cutting needs.

Diameter Options: With three cutting wheel diameters (.215", .24", and .175"), you can optimize your machine for different glass thicknesses and materials.

Angle Customization: The availability of multiple angle options, ranging from 124 degrees to 160 degrees, allows you to achieve versatile cutting profiles, expanding the range of applications for your equipment.

Incorporating these upgrades not only ensures the longevity of your glass cutting equipment but also maximizes its capabilities, providing a cost-effective solution for precision cutting across various glass types and thicknesses.

Download our line card

Click Shop above to browse our NEW e-commerce site

Precision Solutions for Cutting and Glass Processing Excellence

- Aculite CNC Cutting

- Glass Machinery

- Glass Processing Tables

- Auto Freefall Glass Loading

- Insulated Unit Assembly

- Automatic Applicator Table

- Tilt Top Grid Assembly Table

- Prem. Auto Seal Applicator Table

- Prem. HTT Applicator Table

- Easel Grid Table

- LKO Rotating Sealing Table

- Power Rotating Sealing Table

- Cold Single Set Roller Press

- KKO-17 Rotating Sealing Stand

- Hot Melt Clamp Table

- Desiccant Filling Machine

- Application & Hot Melt Clamp

- Glass Processing Equipment

- Glass Inspection Units

- Glass Storage Racks

- Glass Washing Equipment

- Glass Lifting Devices

- Waterjet Machinery

- Glass & Glazing Supplies

- PST Machine Parts

- Services

- Software

- Video Demos